良質なお茶の安全供給を実現するために、

「品質管理」「在庫能力」「流通体制」を整え、真剣にお茶作りに取り組んでいます

FSSC22000認定取得

有機JAS認定

HALAL認証

Kosher認証

やままのお茶作り

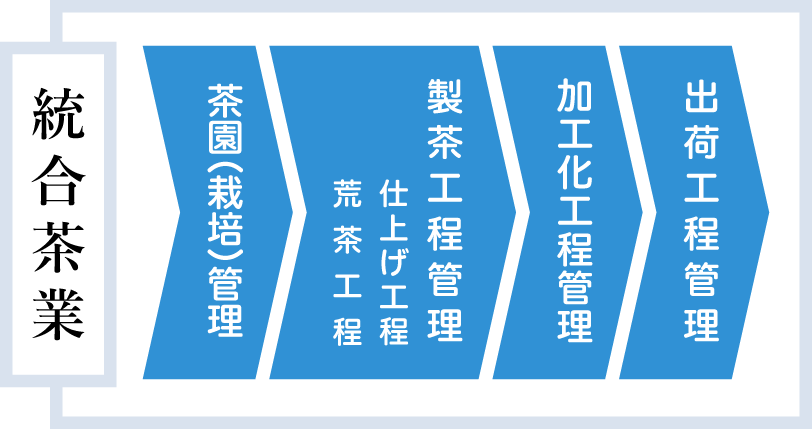

やまま満寿多園の統括管理

こちらの動画をご覧ください。弊社の取り組む統合茶業がわかり易く紹介されております。

茶園(栽培)管理

「トレーサビリティシステム」を構築し、農家と協力し「農薬安全 使用誓約書」「茶園栽培管理記録簿」「茶園台帳」の整備を徹底することで、 安全なお茶の生産を確実なものにしています。 協力農家とは共に茶園を巡回監視し、その年の生育状況の把握、摘採の開始時期や収量予測、除害虫防除を行っています。

製造工程管理

大きく荒茶工程と仕上茶工程わけて管理しております。 工程においてはフローチャートとチェック機能活用の徹底を図っています。 そのような管理業務の見える化を実施することにより、お客様へ「安心・安全」が お届けできるものと考えております。

生産設備

規模

| 本社・仕上工場 | 2,600㎡ |

| 荒茶工場 | 844㎡ |

| 資材倉庫 | 660㎡ |

能力

| 仕上加工ライン | 2,500kg /日 |

| 袋詰包装ライン | 5,000本/日 |

| ティーバッグライン | 15,000ケ/10g/日 |

| 荒茶製造ライン生葉処理 | 13,000kg /日 |

| 粉砕工場ライン | 200kg/日 |

保管・倉庫

| 立体自動冷凍庫 | 416㎡(収容能力:約330トン) |

| 冷蔵庫 | 214㎡(収容能力:約122トン) |

| 粉砕工場冷蔵庫 | 収容能力:約210トン |

食品安全方針

- お客様と当社が共に満足できる食品安全マネジメントシステムを確立し、顧客満足の維持向上を目指します。

- 開発と改善を継続し、お客様に満足いただける商品・サービスを提供します。

- 事業活動に関連する法令:規則を遵守し、食品安全危害の発生を予防します。

- お客様とのコミュニケーションを大切にし、お客様の意見は真摯に受け止め、商品の開発と品質の改善に活かします。

- 人材育成、自己啓発活動を積極的に行い品質・サービス向上に努めます。

- 食品安全マネジメントシステムの維持向上、及び要求事項実現のために、継続的改善を図ります。

- 食品安全方針は、全社員に伝達し、理解し、周知し、維持することを確実にし、定期的にレヴューします。

2016.5月より改訂